|

CRANKSHAFT:

The crankshaft

manufactured with forged special alloy steel accurately machined with fine

ground finish main bearing surface. The shaft is dynamically balanced

ensure smooth operation.

|

|

|

|

|

|

|

|

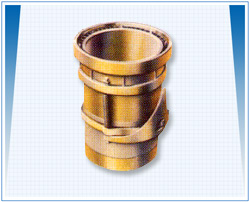

CYLINDER LINERS:

The Liner are of high

grade centrifugally cast iron, accurately machined fine boring. Heat

treated to ensure better quality results. Liner are inter-changeable &

easily replaceable when required. |

|

|

|

|

|

|

|

CONNECTING ROD:

High pressure die cast

aluminum alloy piston. These are fitted with 3 compression & 2 oil

scraper rings to provide efficient gas sealing and low oil consumption.

The connecting rods are high grade SG iron fitted with split in steel

backed white metal lined big end bearings, and bronze small end bush.

|

|

|

|

|

|

|

|

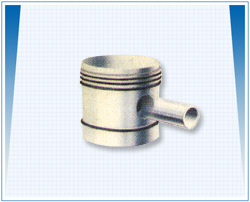

PISTON

Oil operated

manual or

automatic loading or unloading arrangements built in each liner are

provided to give off-load start and capacity reduction. Loading or

unloading of the liner is achieved by the hydraulic / mechanical suction

valve lifting from its seat in the liner collar by sinusoidal spring

tension.

|

|

|